SRS Blog

Building energy efficiency insights from the innovators behind EPICIf an investment has been made in energy saving improvements, a key question building owners often pose is “Are the projected savings being achieved?” While energy savings cannot be measured directly, a properly designed measurement and verification (M&V) program should be able to answer this question. While this may seem simple, as often encountered with energy saving projects – the devil is in the details.

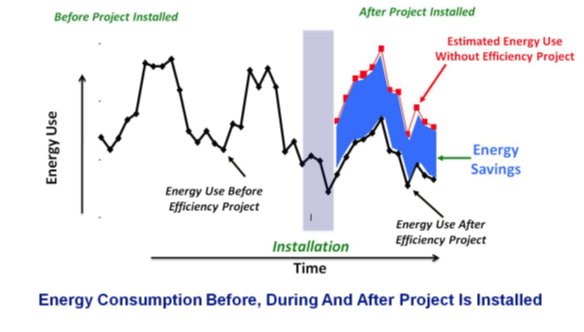

An M&V program involves developing a plan pre-installation and implementing it post-installation to measure and verify energy savings. Implementation of this plan focuses on comparing post-installation energy consumption to what energy consumption would have been in the same time frame had the improvements not been made. Defining what would have happened had the energy improvements not been made (refer to the figure below) represents the fundamental challenge to quantifying and verifying the savings.

Establishing the Baseline

The foundation of a quality M&V plan is a technically sound energy consumption baseline developed prior to installation of the energy saving improvements. This critical first step includes identification of key variables that can materially impact the projected energy savings. It would be much easier if the assumptions that comprise an energy savings projection were fixed. Unfortunately, this is not the case as many of the post-installation data inputs are subject to change, such as:

- Weather conditions

- Building operating hours

- Building occupancy

- Building use

- Tenant modifications

- Tenant types/internal loads

- HVAC equipment setpoints

- Space expansion or contraction, e.g., pandemic impacts

- Maintenance practices

- Cost of electricity

- Cost of fuel, e.g., natural gas.

In most cases, after the energy saving improvements have been installed, it is virtually impossible to re-create the baseline. Therefore, it is very important to carefully define and document baseline conditions as precisely as possible. Any post-installation significant deviation from the pre-installation initial assumptions must be carefully evaluated and appropriate adjustments made to the projected energy consumption savings. Determining the impact of such deviations is critical to the credibility of the energy savings projection.

M&V Time Frame

The next question for consideration is how long after the energy improvements have been installed should the M&V program continue. Experience has shown that most major problems are uncovered in the first year. Hence, the M&V program should extend for at least a full year through all four seasons.

The M&V Program

It now comes down to aligning the scope of the M&V program to the complexity of the improvements and the goal that the building owner is seeking to achieve.

While the M&V state-of-the-art is continuing to evolve, today there are two generally accepted M&V approaches for quantifying energy savings. These include:

- Deemed Savings (DS) Method

- Project-based Measurement and Verification (PB-M&V) Method

Each of these methods is defined by industry-standard protocols that are commonly used by energy professionals asked to quantify and verify savings. Choosing the preferred method in each case will require consideration of multiple factors such as the owner’s objectives, the scale of the activity, and the budget allocated.

The DS Method

Deemed savings (sometimes referred to as “stipulated savings”) are pre-determined estimates of energy and peak demand savings attributable to energy efficiency improvements. Electric utilities often use these pre-determined estimates as a substitute for a formal (pre- and post-installation measurement) M&V program. Deemed values are typically applied to relatively simple, well-defined efficiency measures such as lighting or specific equipment for which the performance characteristics and location-specific conditions are well known. In these instances, the DS approach can provide reasonably reliable and accurate savings estimates.

Deemed savings values are usually documented in resources such as utility Technical Reference Manuals (TRMs). To-date, there are approximately 20 TRMs in use at the state and regional level. While TRMs can be valuable, methodologies in the TRMs for estimating savings can vary widely. Some TRMs include information based on prior-year evaluations including, in some cases, rigorous metering and analysis of actual energy savings from installed improvements. While others have determined savings values based on computer simulations or engineering algorithms.

PB-M&V Method

For more complex energy efficiency projects or for projects with significant savings variability, the PB-M&V method would likely be the preferred approach. When using the PB-M&V method, energy professionals typically rely upon one or more of the following industry best practice protocols:

- International Performance Measurement and Verification Protocol (IPMV), Efficiency Valuation Organization: http://www.evo-world.org

- Federal Energy Management Program (FEMP) protocols and guidelines: http://www.eere.energy.gov/femp/pdfs/mv_guidelines.pdf

- ASHRAE Guideline 14-2002: Measurement of Energy and Demand Savings: https://www.ashrae.org/home

- U.S. DOE’s Uniform Methods Project (UMP) for Determining Energy Efficiency: http://www.energy.gov/eere/about-us/ump-protocols.

The framework provided by the IPMVP has become the industry standard today for most major project energy savings M&V, including projects where energy savings are guaranteed.

As indicated previously, projecting energy savings prior to installation often entails numerous assumptions. Using the PB-M&V method can help quantify these key assumptions and reduce the uncertainty associated with energy savings projections.

A Final Note

It should also be noted that equipment commissioning (Cx) is not equivalent to an M&V program. Cx is a post-installation start-up and inspection that confirms the improvements and their installation meet reasonable quality standards and that the improvements are operating correctly. The objective of M&V is to confirm whether the improvements are generating the projected energy savings.

Fortunately, a new generation of software, data and predictive analytic solutions have emerged that empower project developers and energy efficiency contractors to cost-effectively develop a technically sound baseline to estimate energy savings and facilitate successful M&V. The importance of a technically sound baseline, including weather-normalization, cannot be overestimated in this process. This is particularly important for building owners/investors and asset managers that are increasingly seeking to quantify their energy efficiency project savings in support of their sustainability disclosure and reporting requirements.

To learn more about how SRS’s Energy Performance Improvement Calculator (EPICTM) can assist in establishing a technically sound baseline from which to estimate energy savings and compare pre- and post-installation energy consumption, visit SRSworx.com.

About the Author

Anthony J. Buonicore is Director of Engineering at Sustainable Real Estate Solutions. Mr. Buonicore is a licensed professional engineer with almost 50 years' experience in the commercial real estate energy and environmental industry. He may be contacted through our Contact page.